Getting The Sand Blasting Sand To Work

Wiki Article

The Ultimate Guide To Sand Blasting Sand

Table of ContentsExcitement About Harbor Freight Sand BlasterGrit Blasting Fundamentals ExplainedThe 4-Minute Rule for Mobile Sandblasting Near MeThe Best Guide To Grit BlastingThe Basic Principles Of Sand Blaster Harbor Freight The Of Dustless Blasting Near Me

Steel nozzles will certainly not damage when gone down. Economy and also non-industrial sandblasters for home or DIY utilize usually included low-cost steel nozzles. Based exclusively on wear resistance boron carbide and also binderless WC last as much as seven-time longer than concrete WC. If you bang a boron carbide or silicon nitride nozzle into a component, grate, or closet wall surface, then the nozzle is most likely to split compared to a cement tungsten carbide nozzle.The unpleasant blowing up procedure removes the surface contamination and transforms it right into dust. The dust as well as media are dealt with using dust enthusiasts, industrial vacuums, and separators. Rough guns can gently remove graffiti, paints, and also coatings without the elimination of the base product - harbor freight sand blaster. The rough blaster can additionally deeply blow up a steel surface area to totally eliminate any type of corrosion, scale, or adherents to a NACE/SSPC "white metal" cleanliness quality.

Next, the surface area is peened with tiny rounds or microbeads to fine-tune the surface area finish. If the component has a harsh (high roughness standard, Ra) surface area coating like an as-cast or as-forged surface, after that peening can modestly refine the surface coating. If the part has actually been ground or machined to a smooth or reduced Ra surface, after that fired peening will certainly cause a rougher surface finish.

Some Ideas on Sand Blaster For Sale You Need To Know

Finishing, paints, and adhesives stick far better to a rough surface area contrasted to a smooth surface. An abrasive blasted surface produces a support account with undercuts and also more surface for layers as well as adhesives to grab onto. A sandblast roughened surface area on a stainless hand rails aids people obtain a much better grip also.

Corrosion and also corrosion layers need to be removed also, specifically for safety coverings satisfying the National Organization of Deterioration Engineers (NACE) and also Society of Surface Protective Coating (SSPC) requirements. 3 factors to get rid of corrosion or rust with unpleasant blowing up are: Rust as well as corrosion layers are weak and softer compared to the underlying steel.

The Ultimate Guide To Abrasive Blasting

A blast roughed up surface gives mechanical interlocking in between the finishing as well as substratum. No, since if a surface is as well harsh, after that thinner safety finishes could not completely cover the surface area causing pinholes and corrosion of the underlying surface area. Shot, grain, and also rough blasting can reduce some additional hints of the high tops in a surface area profile to boost rust safety coating efficiency.Medical/ Oral Cleansing, covering preparation, etching, and also polishing of medical tools as well as oral reconstructions. The investment or mold product on cast crowns or bridges can be delicately removed with a tiny benchtop sandblaster or micro-blaster. Hip, shoulder, dental and also various other bone, and joint implants are blast cleaned up to fulfill rigid FDA cleanliness needs.

5 to 5 microns). Particular materials such as lead-based paints and heavy metals create unsafe or harmful dirt when blown up. In these applications, specialized systems are required to avoid the launch of unsafe products. Proper collection, managing, as well as disposal of the media are needed. Wet or water blowing up systems decrease the dust problem.

The smart Trick of Sand Blaster Harbor Freight That Nobody is Discussing

Media as well as palatable wear components need to be gaged to preserve consistency and also then fixed or changed at suitable intervals to guarantee top quality and also security. The price of media and consumables must be factored into your sandblast closet selection process. Sandblasters or sandblasting operators can be hurt during abrasive blasting. The high-pressure Find Out More rough stream can harm skin as well as eyes.Soda, solidified carbon dioxide, as well as wet blasting keep components great throughout blowing up. Abrasives as well as blast media can obtain lodged right into gaps on a part as well as can be hard to remove. VII. Choosing as well as Purchasing Sandblast Cabinet Start with the dimension, shape, as well as annual production quantities when considering the type of blowing up tools to choose.

Validate the blowing up procedure parameters with an additional examination or trial. What are the palatable costs such as blast media, put on component replacements, and system maintenance expenses? How lots of drivers are needed to run the blast system?

Some Known Questions About Sandblasting Near Me.

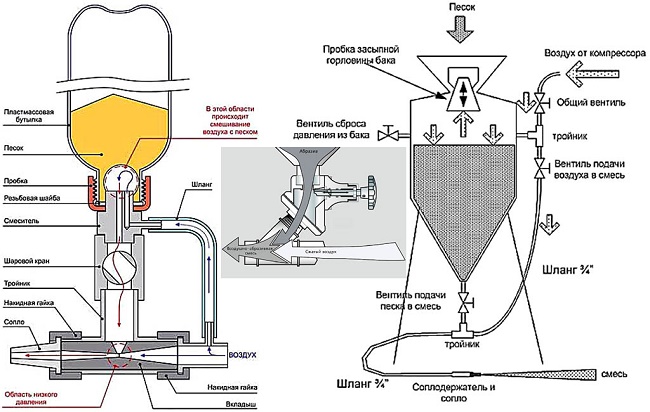

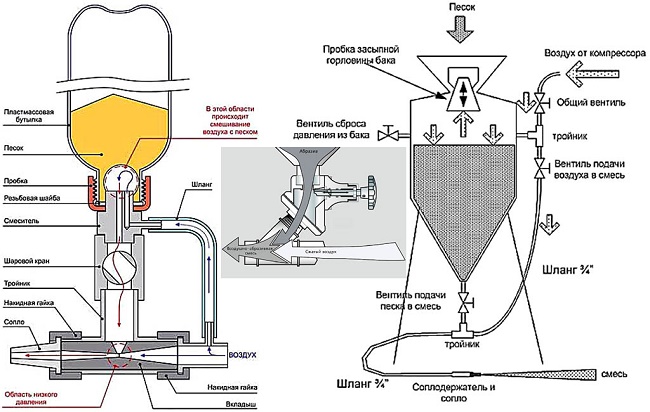

The first of the three kinds of sandblaster is the gravity-fed design. There are 3 standard components to this model: an air compressor or pressurized air storage tank, a hand-held stress weapon with airline as well as a receptacle on top of the weapon. The hose links to the air tank, and also the receptacle is loaded with silica sand.

They contain a large canister containing silica sand under high pressure. This is a bit comparable to the concept behind an aerosol can. A sandblasting gun, look what i found normally a two-handed version, is connected to the port on top of the cylinder using a specialized hose pipe that can withstand the abrading impacts of the sand.

The 9-Minute Rule for Dustless Blasting Near Me

Report this wiki page